FABtotum’s Printing Head PRO: a new professional approach

FABTOTUM is yet ready to take its FABtotum Personal Fabricator to professionals with its upcoming hi-performance Printing Head PRO.

The FABtotum goes PRO

With the capability of switching heads, the FABtotum Personal Fabricator is an evolved 3D printer that can 3D print, mill, engrave, laser cut and more.

The Printing Head PRO is the first head module of the FABtotum PRO line: a full new set of Heads will be announced during the 2017 and 3D printing is the first function to take advantage of this (r)evolution.

What’s new with that? What’s the difference with the previous Printing Head V2? There’s more than one.

The new concept, of course, will still benefit of the main idea of the project: retrocompatible with all the FABtotum models, both the first Personal Fabricator and the CORE edition, the Printing Head PRO brings top tier 3D printing to the FABtotum Personal Fabricator.

Directly thought to be the solution

The Printing Head PRO is a direct-drive system.

Thanks to its fast and precise filament control, objects are sharper and more detailed than ever, even with complex structures that require loads of retractions.

Oozing, Stringing and other filament related issues are a thing of the past.

PRO stands for professional

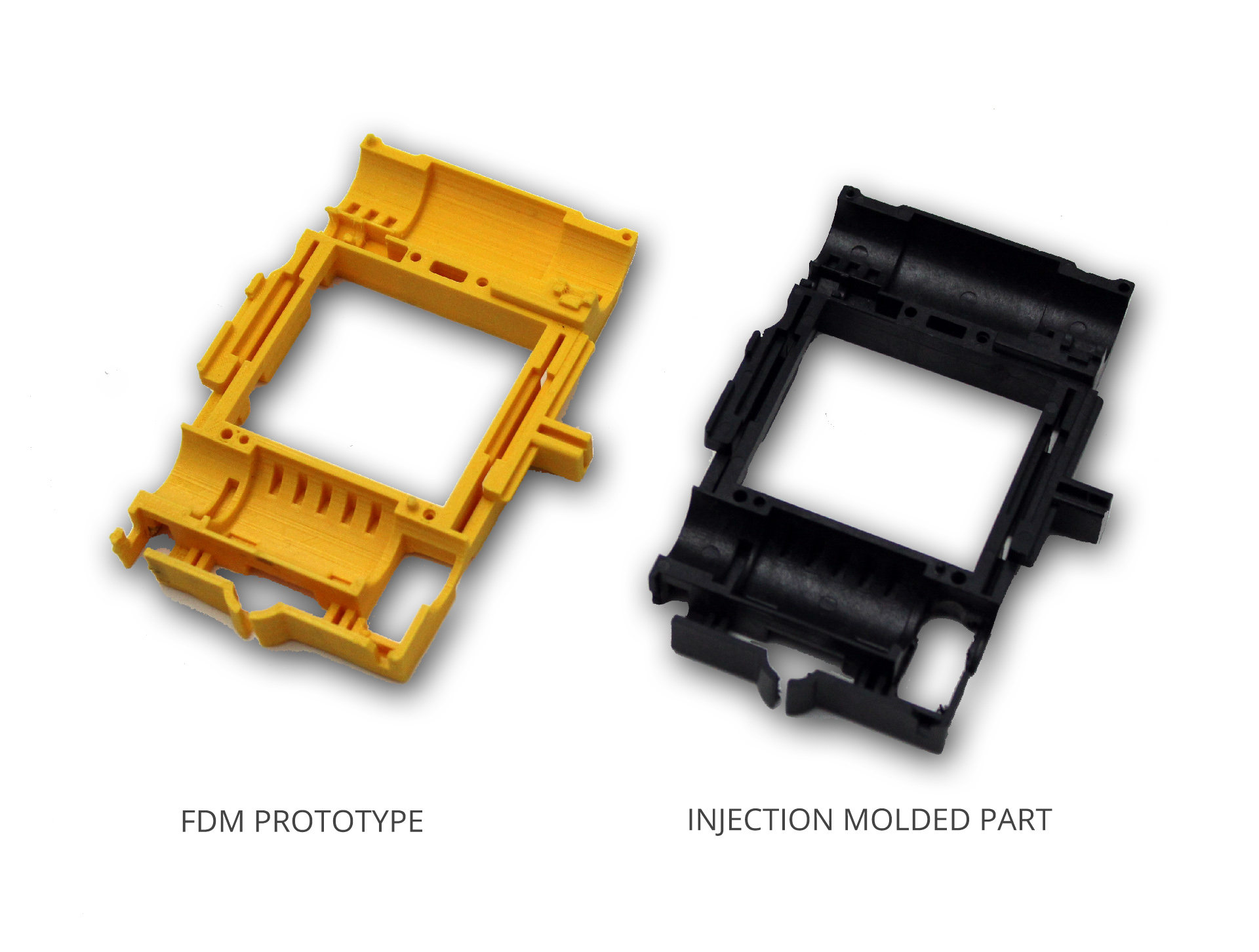

Precise, long lasting, reliable: all these qualities describe the Head as much as the final objects. The Printing Head PRO is the definitive solution for all 3D printing manufacturing needs on the FABtotum Personal Fabricator platform. It aims to serve a businness when a pre-production phase is required or prototyping is one of the most important steps before the final product is designed.

The Printing Head PRO can support continuos production batches and effectively run for days at a time. The Printing Head PRO is also a big step forward the expanding market of materials. Flexible filaments, special and exotic mixtures are all easy to be printed thanks to the Direct-drive system and to a renewed cooling solution.

A closer look to the Head

Unlike other printers, the FABtotum can take advantage of its unique hi-torque gantry, originally thought to sustain Milling Head’s subtractive motor. Speeds are not compromised, quality is higher.

Based on the FABtotum Print Head V2 Nozzle design, the Printing Head PRO features exchangeable nozzles, serviceable hotend, a filament fast-release lever and a full metal hot end.

A dedicated power circuit grants low heating / cooling times: the circuit will work both during the pre-print phase and during the final task.

Cooling is granted by a triple fan system that ensures manufacturability even in the hardest spots on big and small objects with few or lots of separated parts.

Bridges, overhangs, holes, steep angles: everything is doable with a Printing Head PRO.

The essential solution

Thanks to a new active retention mechanism, the Printing Head PRO will be very permissive of filament density and physical proprieties. But the biggest advantage of the Printing Head Pro is its efficiency for long tasks and pre-production runs: batch printing, serial production of prototypes are now easy achievements for every businness.

A quick overview of the specifications:

- Autonomous Direct Drive System;

- Filament quick release lever;

- Stainless steel protection shield;

- Exchangeable brass nozzle (one is 0.4, optional 0.6 mm, more coming);

- Thermistor, heating cartridge for cleaning and servicing;

- Extruder is made from a Full metal Body with 6mm PTFE Liner;

- Inox steel melting chamber, with heatbreak to stop thermal flow to the head;

- Aluminium heat sink to cooldown the body and PTFE liner;

- Max temp: 240°-250°;

- Materials: PLA, PETG, ABS, NYLON (to be tested HIPS, PC).