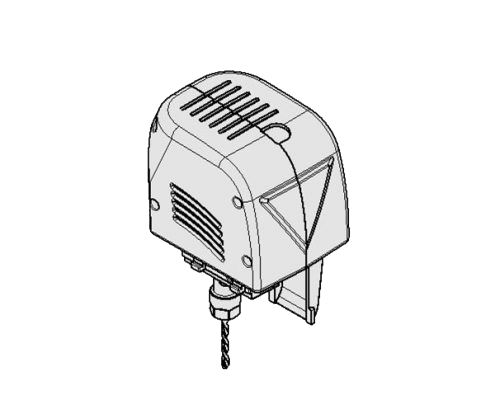

3D Milling Head:

your home CNC milling machine

Transform your FABtotum in a desktop milling machine

The FABtotum’s Milling Head add-on is made for Engraving, Milling and Cutting many common materials.

The Milling Head is a 200W brushless motor able to carve, engrave, cut, mill different materials like woods, light metal and non-metal alloys, as well as prototyping foams such as urethane.

With speeds up to 15’000 RPM it can also do engraving on PCBs, enabling a whole new world of embedded rapid prototyping with your FABtotum Personal Fabricator.

Why using a CNC machine? What is it used for?

A CNC milling machine is useful to create 2D and 3D objects with high precision. This kind of device is used in big sizes for industrial mass production. A smaller version, like the FABtotum’s is perfect to fit the gap between big and small companies. This tool is perfect when the need of rapid prototyping with a different material arises. While 3D printing can rarely (as for today) create something different from plastic, a milling tool can cut off or engrave many materials such as cardboard, foams, woods, metals or even PCBs. The result will be of an higher precision compared to additive manufacturing and the surface will be smooth.

A CNC machine on a desktop can be of great help for many areas of interest: from architecture to design, from dental and medical to toys and customization.

Modeling foams can be of many kind (see CNC and Rapid Prototyping Materials) and can provide great results for scaled landscapes and human body parts; woods and metals might help when reproducing buildings, tools, plates and toys. Milling PCB without using chemicals is just a quicker and safer way to develop new projects. If you wish to know more about different choices, read the dedicated Materials page.

The hardest part is choosing the right bit. There are thousands of choices.

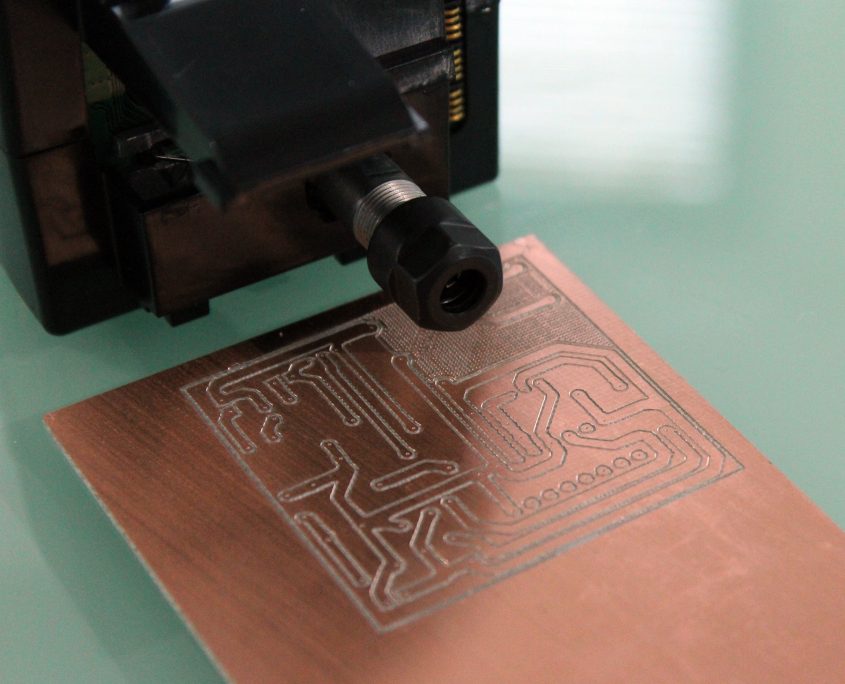

PCB milling for Makers and Hobbyist

PCB milling is the process of removing the copper from a PCB according to a specific design, in order to create a circuit.

With the Milling head and a standard V carve milling bit it’s possible to create fine and detailed PCBs.

The Milling process is simple and straightforward and can be executed with a very limited knowledge of CAM software.

Being able to design and create PCBS is very empowering: create functioning applications, use integrated circuits and mix this technology with others available on the FABtotum!

Create a PCB, solder components and 3D-print it’s custom-made enclosure. All from one device. How cool is that?

How to choose the best milling bit?

The Milling Head uses standard ER8 collets and 1/8th inch bits (3.175 mm).

You may choose the best milling bit depending on the final goal and the material used.

See the “Parts and Accessories” and Materials for Subtractive Rapid Prototyping for more details on the different surfaces. The ones that can be used on a FABtotum are “end mills”, as they must be used with the provided ER-8 chuck. Among this category, a wide range of possibility is still available to better choose the right tool.

Here are a few examples: