CNC and Rapid Protyping Materials: A Brief Overview

The FABtotum is able to switch from additive to substractive function with a simple gesture: just take the Printing Head off and place the Milling Head or Laser Head on.

The range of materials is wide and for every task a different one is required. Once the material has been chosen, the second step is to find the right milling bit as explained in the Milling Head thread. As a further option, a Laser Head might be preferred.

A focus on the different surfaces can be of great help to understand why one is better than another.

The FABtotum can work foams, woods, thin metals, cardboard and much more. They should be picked for their finishing and final use. PCB milling is one of the most interesting uses.

CNC materials are not all the same

FOAMS

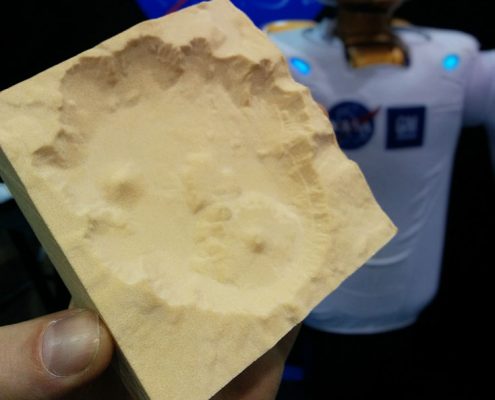

Polyurethane foams are mainly used for modeling as they are quite soft and the finishing is very smooth. Curves come out nice as well as angles. There are many kinds of foams: the softest are common to be milled to create landscapes, toys; the hardest ones can be used for prototyping in many fields, from architecture to automotive.

Even these can be found in different densities, which will give completely different results. Low-density are normally softer and easier to be milled. They are the best choice when landscapes are needed to be reproduced. Modeling finds in these ones a good balance between final performance, quality and price. Thicker ones will be harder, stronger and will have a higher resistance. They can be used from footwear appliances to automotive ones for example.

Milling bit: Fluted Ball End Mill*

GYPSUM/PLASTER/CLAY

All of them can be milled with a FABtotum Personal Fabricator: these raw materials are quite easy to be found and will get a smooth finish. Gypsum, being a pressed powder, will be very precise and can be faster to be worked as a higher speed can be used. Plaster and clay might be difficult as they are fragile and break easily. It is still a good option as an alternative to foams.

Milling bit: Fluted Ball End Mill*

WOODS

The result is similar to the foams’ one, so it depends more on the final use. The FABtotum is able to carve woods as deep as the milling bit can go: the most used and top quality are red woods, oaks, balsas and birch. Laminated and plywood are fine alternatives as well. It is important to decide the right speed in order to avoid damages to the material. The FABtotum can cut off or simply engrave woods on three axis. Fourth one is installed as standard equipment and can be used as well, but generating the right GCODE might be tricky (this applies to the already mentioned materials as well). Woods can be the right choice for plates, signs, modelling and much more. To engrave, there are two alternatives: Milling Head and Laser Head.

Milling bit: Fluted Flat End Mill*

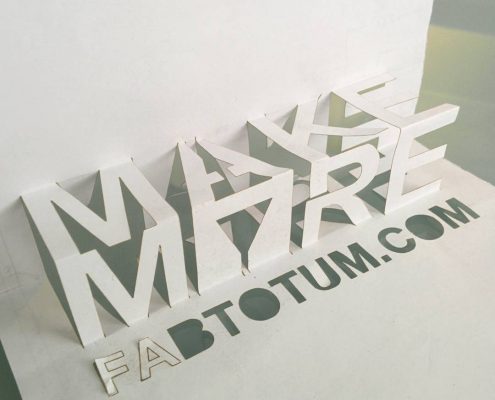

PAPER AND CARDBOARD

Where the Milling Head would fail as the material is too thin or soft, the Laser Head will do. Paper sheets can be engraved or cut, depending on the final use. The idea is to draw or write on them if a very nice finish or high precision is required. The low power can be a good decision as it will allow to get results otherwise impossible to achieve. a 500mW, therefore, is more than enough for these materials. Laser cutting on a desktop product allow to create infinite objects and shapes: cardboard can be cut flat and reshaped on a second phase.

Milling bit: None!*

METALS

Harder but not enough, the FABtotum can carve and cut some metal alloys as well. Speed must be slower and the maximum depth for each pass depends on the diameter of the milling bit and the material. Going too deep might damage the motor and consume the milling bit. The possibility of milling metals with a desktop device is of great help when rapid prototyping is needed in a short time: no need to ask to third parties, which will also allow to save some budget. It is also a good option to run a test without actually cutting the material, in order to spot any possible CAM issue.

Aluminum is a good option as it is normally easier to be cut. With a FABtotum and the Milling Head it is therefore possibile to create metal plates, signs, small tools or small mechanical parts.

Milling bit: Fluted Flat End Mill*

PCBS

This has always been a great alternative to the long procedure that needs many processes, involving chemicals and other special materials. With the FABtotum it is easy to peel off the board exacty where needed before soldering. It is as well possibile to cut them or to mill doublefaced boards. It just takes a bit of attention to avoid common mistakes like misplacing.

For fully working PCB you can combine Laser Head and Milling Head’s functionalities, depending on the final result needed.

The precision here is fundamental if the Milling Head is the chosen one: a very pointy bit will be needed and spinning too slow might be worse than speeding up.

But the big deal is the laser, which is able to draw thin lines or polimerize the material which the acids will take off.

Milling bit: V Carve Mill*