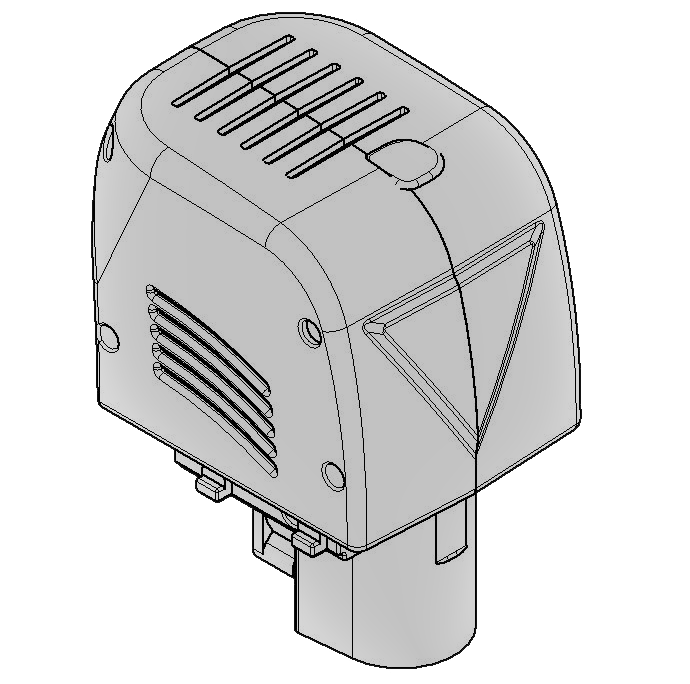

Laser Head: the laser cutter

for your FABtotum Personal Fabricator

The laser head will help you getting the best from you Personal Fabricator

The FABtotum Laser Head is equipped with a A Class 3B laser module (up to 500mW), enough to both engrave and cut, depending on the chosen material.

It’s assembled from premium EU and US made components and optics, each one assembled and tested for continuos operations in our facility.

The Laser Head features a onboard active cooling with temperature control and smoke dispersion (to prevent damages to the optics).

The Laser Head also features realtime power tuning, so that you can correct the power of the output on some materials or have different levels of engraving.

It is not meant be a substitute for the Milling Head: these two can perform different tasks which cannot be achieved with the same head.

For example the Milling Head cannot engrave with the same precision an optical module can, but at the same time the Laser Head cannot cut thick materials or reflective surfaces.

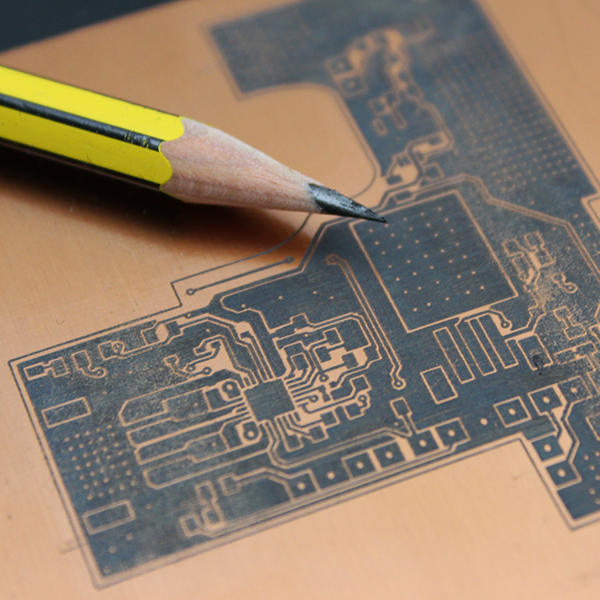

The Laser Head, however is the winner when it comes to create stencils, engraving PCBs, pictures, or cutting cardboard or balsa.

CAM toolbox software

The Laser Head comes, bundled with 30 days free of CAM Toolbox laser module, FABtotum’s own online laser postprocessing application, that helps you create gcodes from images and vectorial dxf for your laser head.

With it and your source file you will be easily be able to generate the Gcode for your Fabtotum and Laser Head for all your needs:

- PCB engraving with photosensitive masks( phositive and negative) from raster images

- PCB engraving with photosensitive masks from Vectorial DXF.

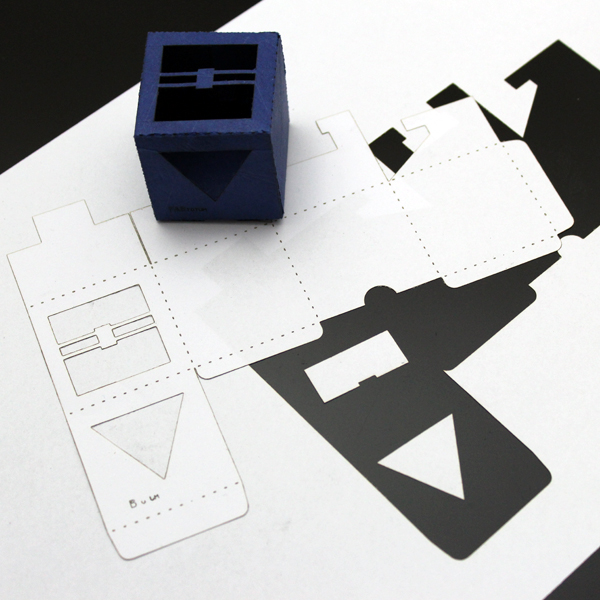

- Cardboard and paper Marking from raster images and DXF

- Card and paper engraving from raster images

- Balsa and Wood engraving from raster images

- Balsa Cutting from DXF

- Coated aluminum tags engraving from raster.

- Coated aluminum tags marking from DXF.

- Origami-like features with cut and fold lines on paper and cardboard

CAM Toolbox requires the FABtotum unit to be connected to the internet and a valid subscription and FABID.

Without using CAM Toolbox you may still run your own generated or postprocessed gcodes from third party CAM software uploading it to the FABUI own Project manager.