Solder Paste Dispensing head by S&I Engineering

A few Projects we covered are as structured, well documented and useful as the one from S&I Engineering, a Greek Company specialized in a series of digital manufacturing, software and hardware oriented activities.

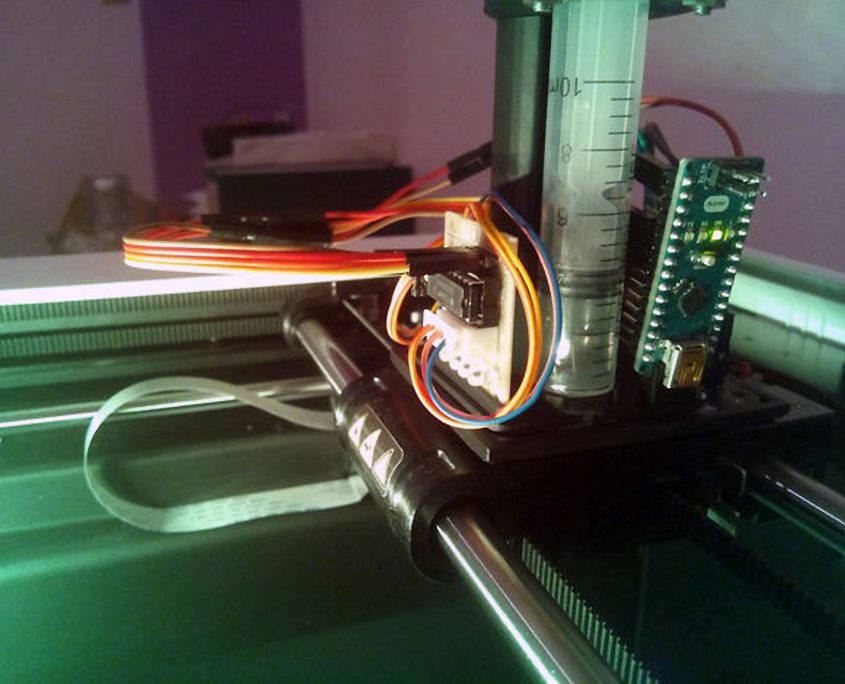

The project in question is a Solder Paste Dispensing Head, a custom FABtotum head build upon FABtotum own Head Development Kit (HDK) capable of Solder paste deposition. By using the FABtotum as the multipurpose platform it is, they were able to use it to lay drops of solder paste on printed circuit boards (PCBs).

In other words this custom head is meant to do the dirt and boring job of preparing PCBs for soldering in the reflow oven, a huge advantage when dealing with very small quantities of prototypes.

There are many reasons to take a look at this project:

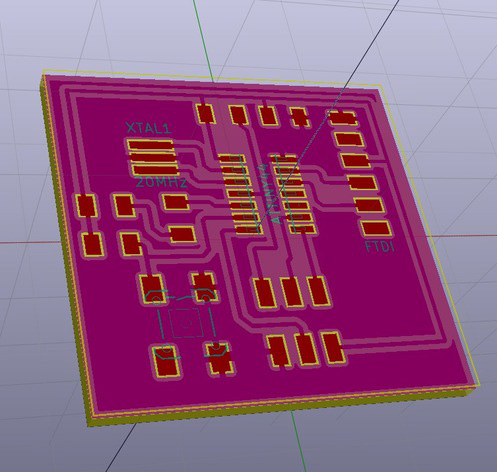

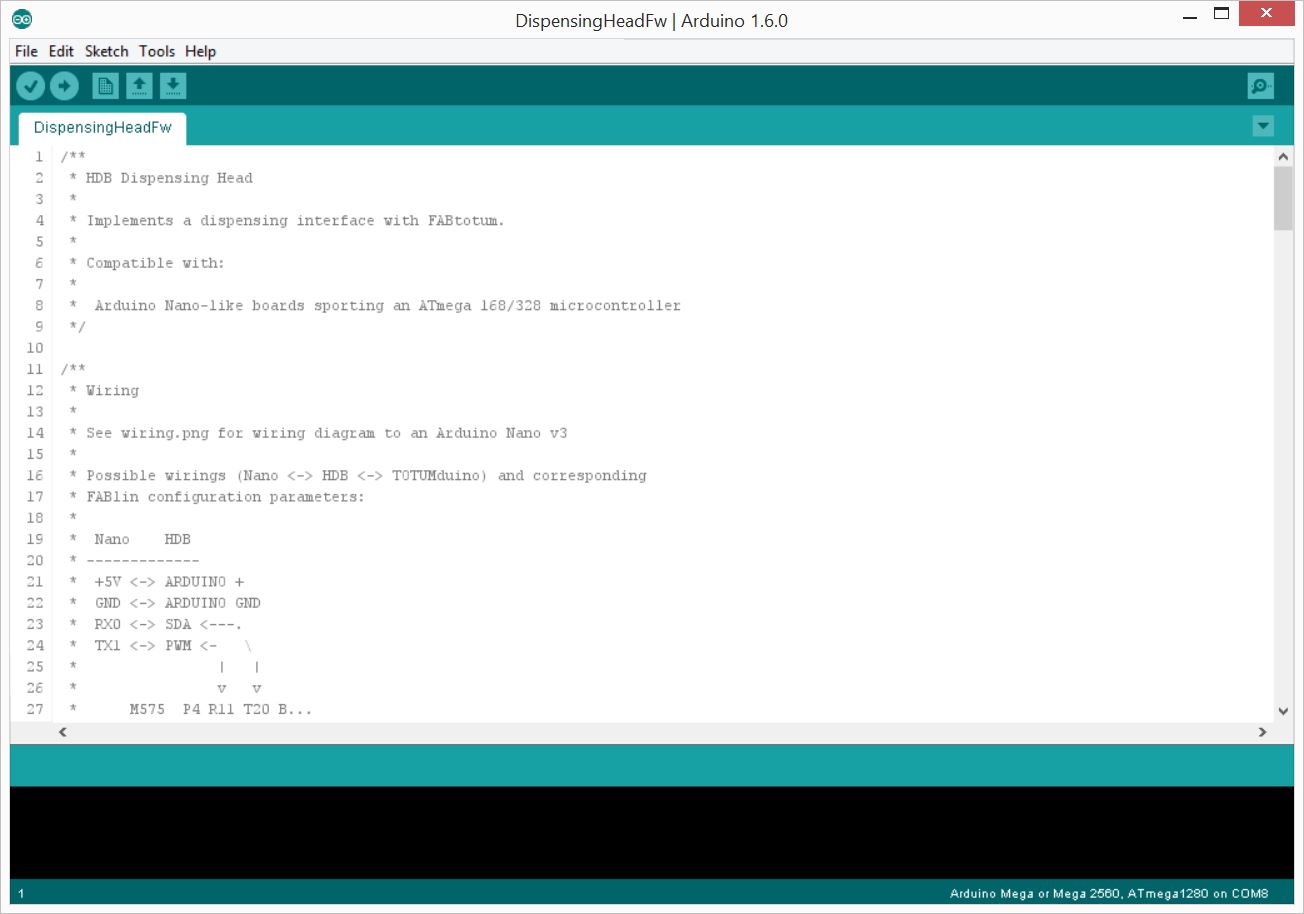

- It’s made with off-the shelfs components for the most part.

- The remaining components are easily replicable on the FABtotum itself with 3D printing, Laser Engraving or PCB milling.

- All the parts, codes and PCB layouts are provided.

- Assembly and everything else is well documented.

- It actually solve a problem.

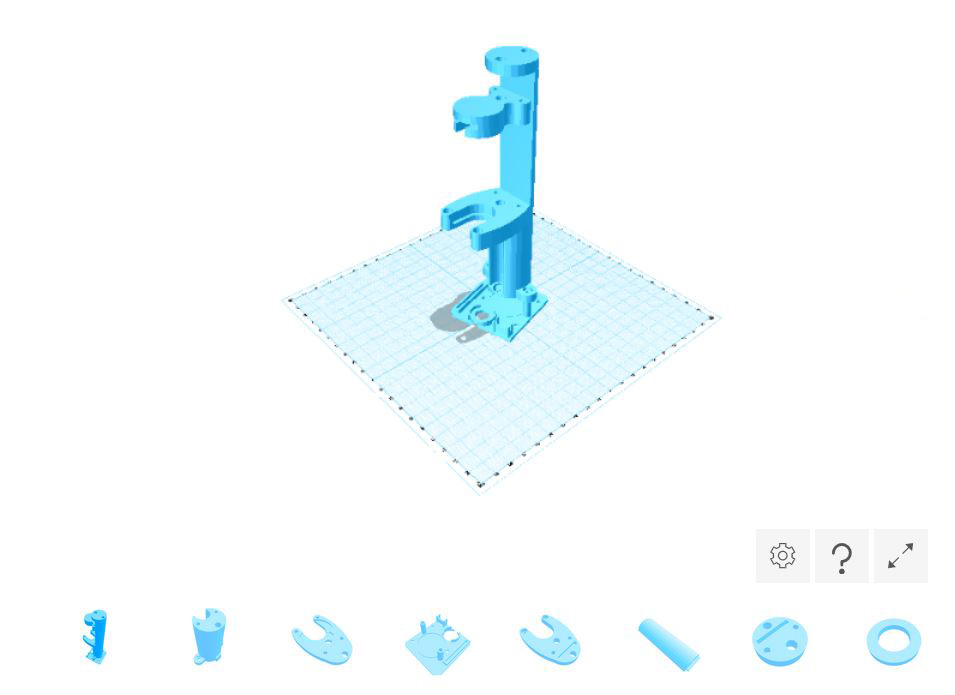

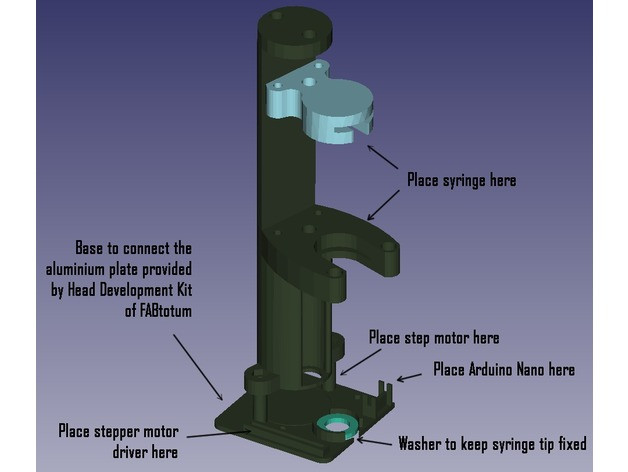

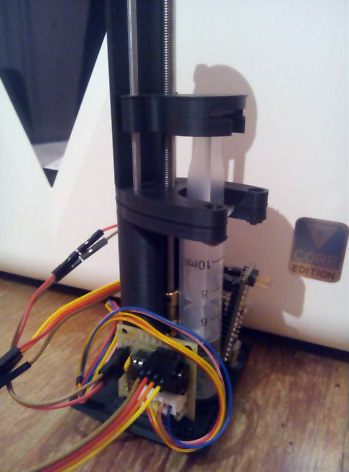

The 3D printed parts

The mechanical components (nine in total) are used to convey motion from a stepper motor to a leas screw that in turn squeezes a siringe.

During the project these componets have been adapted from TwinTeeth design then 3D printed with the FABtotum personal fabricator itself.

On the left the assembly (minus the electronics, syringe and motor) is presented.

The base in particular has been modified to be fit the Head development kit and in particular to screw on the metal plate provided with it, on top of wich the head development board itself is mounted.

Aside from the syringe moveable clamp (on top) there are no 3D printed moving parts.

The total assembly is a bit higher than the standard head enclosure so it had to be mounted without it.