FABtotum files for liquidation.

We regret to inform that following a stakeholders decision FABtotum SRL is putting the activity on hold and liquidating his assets voluntarily.

A rapid shifting market and lower sales from 2016 to 2018 have created a condition of unsure recovery and profitability, culminating in this decision.

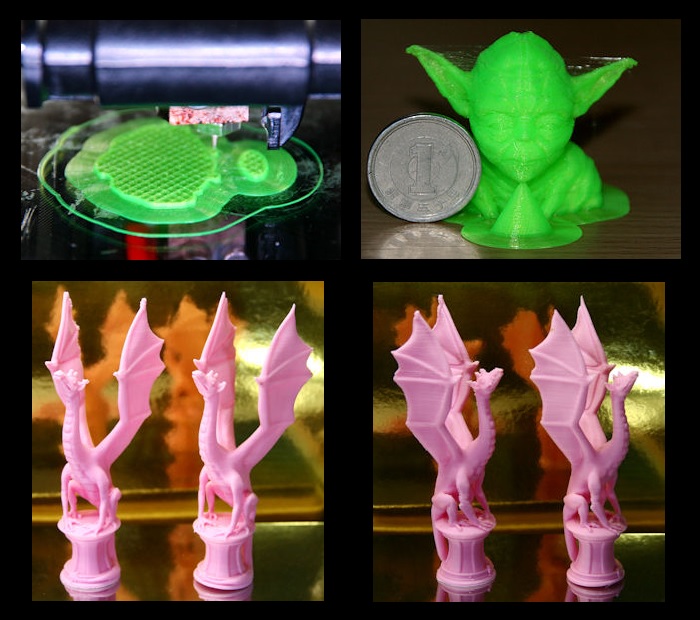

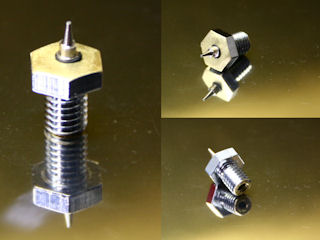

Following the crash of consumer 3D printer sales in 2016-2017, the new products in the B2B market were still not performing well in terms of units sold, despite the appreciation for the products.

Potential investors were not willing to finalize an offer in a dwindling market and strategic partnerships were taking more than expected to gain momentum in a very competitive arena.

To avoid increasing the debt with investors, suppliers and banks a voluntary debt relief liquidation has been filed.

The liquidation procedure, officially and lawfully filed, will carry on until debt relief is completed.

Anticipating this situation sales via the FABtotum online Store have been stopped beforehand.

The online services will continue to operate in the next weeks, giving access to documentation and all the website.

Online Support and email support have been temporarily terminated.

A FABUI patch will release soon to allow “Local Access” of the FABtotum FABUI software (bypassing the FABID login automatically).

The FABtotum Github account will still provide the open source code for all the FABUI software , the FABlin Firmware and FABtotum hardware.

While disappointing for everyone involved we hope with this measure to foster the conditions for FABtotum to continue making innovative solutions in the AM & 3D printing industry.

We would like to take this opportunity to thank our partners and you, our customers, for your past business and trust.

Last, would like to thank our staff for their daily commitment, dedication and teamwork.

FABteam