PRISM development update

Hello everyone!

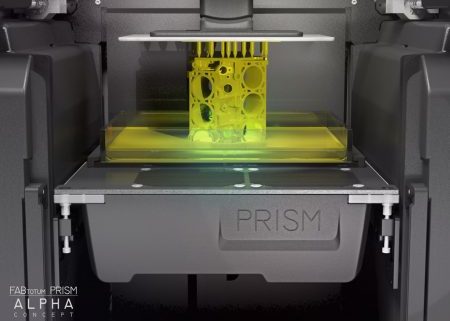

We’d like to update you on the development of the PRISM module.

Keep in mind that nothing is definitive or guaranteed to be part of the final version.

Content of this update:

- Changes in vat & platform design

- Changes in the emitter design

- Electronics and screen design

Changes in vat & platform design

We have been updating the design of the vat to be more affordable to service and easy to print on.We started off with a simple drum-like vat design, where the bottom of the vat is a flexible PET film. This reduces the strenght needed to separate the layer from the vat bottom and subsequentially reduces the time to print.

The initial design wasn’t very friendly when it came to calibration and replacement.

Below you can see the first attemps.

The red ambient light is actually used to see without introducing wavelengths close to the curing wavelenght of the resin.

Once the design change was giving promising results we moved to a more elegant setup, where the vat is removeable but can retain the tension of the FEP sheet.

Removing the vat from the platform (e.g for cleaning it) is critical and very annoying if you are unable to do it without removing the entire platform.

the FEP drum sheet will need to be changed once in a while but it’s a more simple and effective solution than a rigit vat.

when tension is applied to the vat the sheet bends and the part is detached much more easily.

To give you some perspective, during some tests we broke the fixed vat bottom, because the force applied to detach the cured layer from the bottom of the vat was exceeding the max shear force of the glass.

As for the platform, the solution below is giving good results.

Be aware that the locking mechanism is not the final one and it’s the result of a quick assembly to test the VAT and the platform itself.

Below you can see an adhesion test (and the feets of a Marvin Keychain print starting to grow).

The platform is brushed aluminum with an extra treatment to give it more adhesion.

It will require some light brushing once in a while to maintain the perfect adhesion.

we are also experimenting with different alloys to decrease the need of this treatment.

Changes in the curing light design

We have been testing different hi-density power outputs (starting from 0.007 W/sqmm). There is an upper limit to the amount of radiation the current screens used can handle. When the threshold is surpassed you either get a permeable photomask (meaning you are curing everything and not just the current layer) or you are damaging the screen.

In order to print to the full extent of the screen, the emitters have to be perfectly perpendicular.

In the original design the light was pivoting and thus getting caught in the pixel matrix when the angle was too shallow. This is no more the case.

Also, originally the system was using 500mw lasers, which normal citizens can’t legally purchase and sell in the EU, except for special applications.

The laser was focused in a single line, but other than that the entire surface was not being cured. The result of this change is that we have a slightly lower energy density (e.g. 0.008w/sqmm) but can cure more area at the same time, taking advantage of the LCD photomask precision.

Electronics and the screen design

Electronics and the screen are a critical component. We are evalutating other resolutions that might be easier and faster to obtain. Compatibility with existing hardware is a key factor in this decision and admittedly a difficulty, as the Raspberry PI cannot output higher resolutions.

The example above was produced with a unfocused array, and produced a less precise result, but has validated the changes outlined above.

We’ll keep updating you with meaningful updates as soon was we have more to share! Stay tuned.

FABteam