Behind the scenes: Production Facility

As the production is kicking off, we shifted the topic of this blog from software & hardware development to industrial/production related topics.

This is going to change soon as we’ll -hopefully- have more time and more details we can share about developing hardware and software on the FABtotum, on ideas we would like to foster and see grow.

In the meantime we tought it would be cool to show how the assembly procedures outlined in a recent blog entry unfolds in reality.

This ensures all building platforms have the same alignment (flat). Power tools allow fine control over torque on bolts and screws when assemblying.

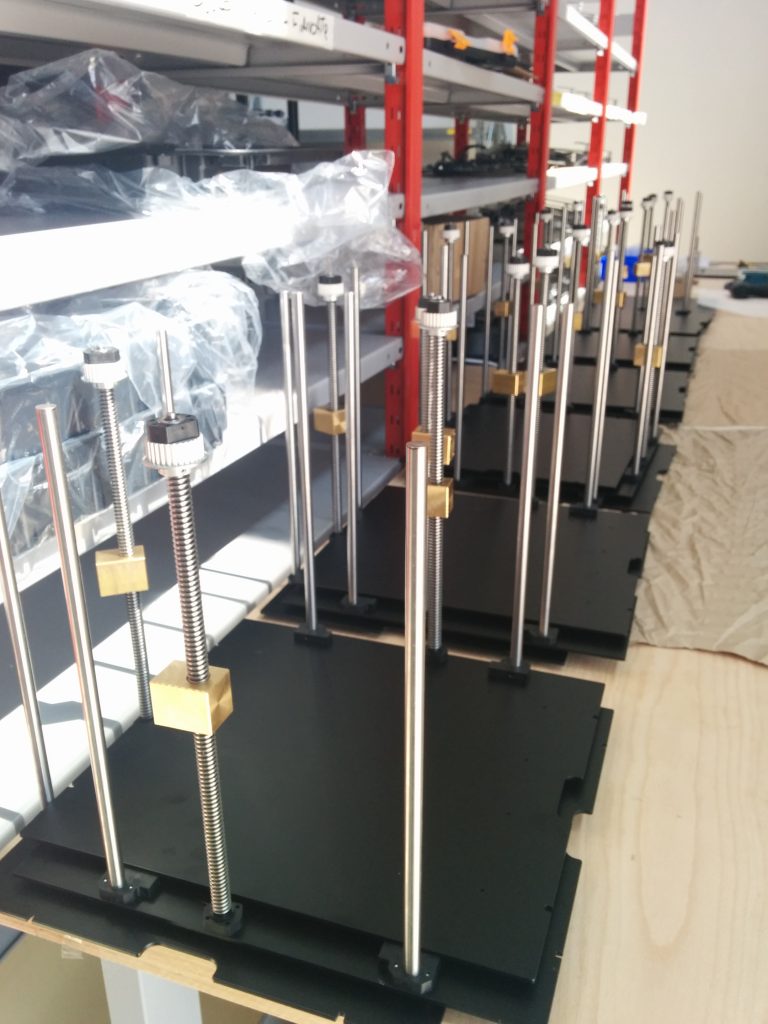

The Z-Axis Subassemblies ready for installation

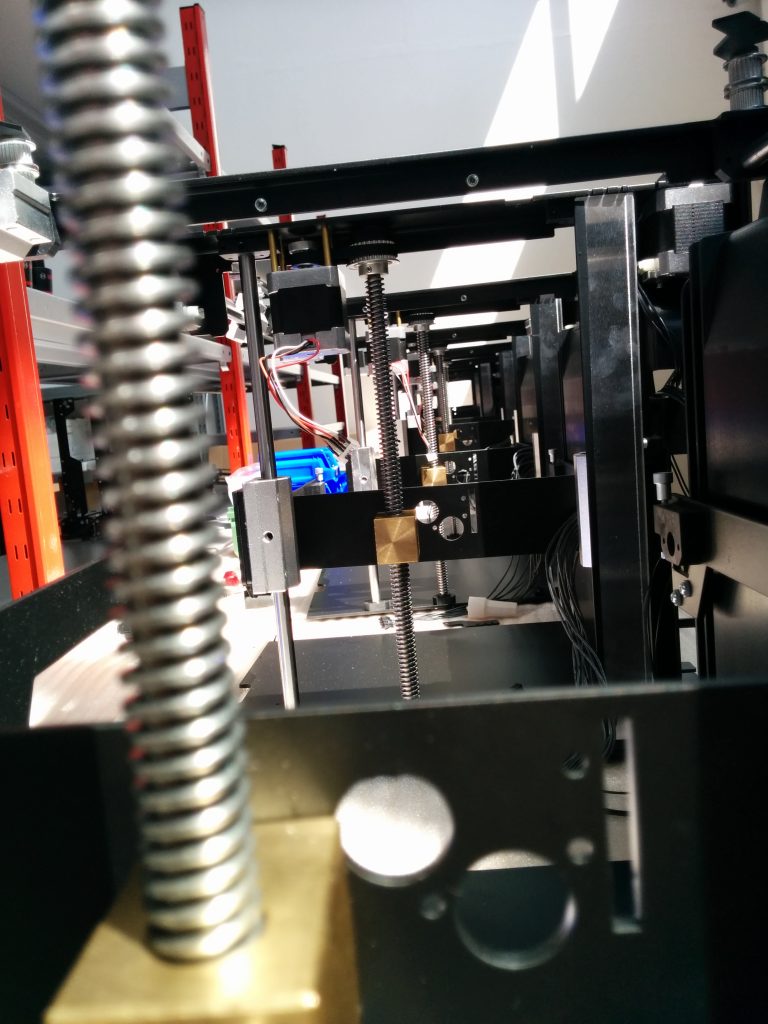

Detail of the Z axis Assembly with the Z axis mounted.

Dust gets blown away with a compressor before we ship.

The first mechanical sub-assemblies on the assembly line! The Personal Fabricator is assembled by joining all the remaining sub-assemblies. It is then moved on another shelf for the final test before packaging.

Early Birds backers: yes, these are units of the Early Birds Batch and Batch 1, these are yours!

More units being prepared for installation of the electronics

Admittedly we’re still moving tables around when needed, because no matter how good you plan your factory floor, you always discover a better way of doing it…by doing it!

In the end all the optimization of the design is paying back now, with low assembly times and reduced possibility of errors that in turns should translate in a better product.

So that’s it for this tech update.

Time for us to get back to assembly, screws won’t screw themselves, right? (?).

In the meanwhile , have you enjoyed the tour? let us know in the comments!