2014 World Maker Faire, New York

Hi guys!

We just came back from the 2014 Word Maker Faire in NYC.

As you may know we jumped in the Faire at the last moment, and we where able to get a space and organize all the logistics at the last minute. Here’s how it unfolded…

Me (Marco) and Andrea jumped in a plane heading for NY’s JFK airport Thursday morning, with Bags full of samples, parts and everything necessary.9 hours after we where landing at JFK Terminal 8.

We arrived one day ahead to rest a little and be able to recover from jet lag before the faire weekend.

At the customs gate I got asked to explain the nature of the 3D samples I had with me. They where probably worried those had a value and I was going to sell them in the US.

The short lady officer was looking a bit perplexed as I explained that those where 3d-printed or carved out of materials with a machine, and we where attending a faire where the “act of making” is showcased instead of the product, so I wasn’t planning to sell anything.

I had each sample wrapped in bubble wrap, and she asked me to unpack the first.

“This is 3d-printed from a plastic filament” I explained. She stood still.

She wanted to see more. “This is carved out of plywood” I continued.

She did the same with all the samples I had carefully packed, forcing me to unpack.

“You made this?” she asked. “Sort of. the machines we make made those.”

She quickly grasped some of the samples and stared at me.

I tought she was going to kick me out, search me or something, then she jumped off the seat, ran off to her colleagues in the customs and said: “Look, these are made by a machine, how cool is that?”.

I nervously smiled as she pointed at me in the distance with the crowd of traveleres watching the scene in absolute silence. She then came back to her post. “That’s really cool. You can go now!”.

Maker Faire NY was already started. Thanks officer.

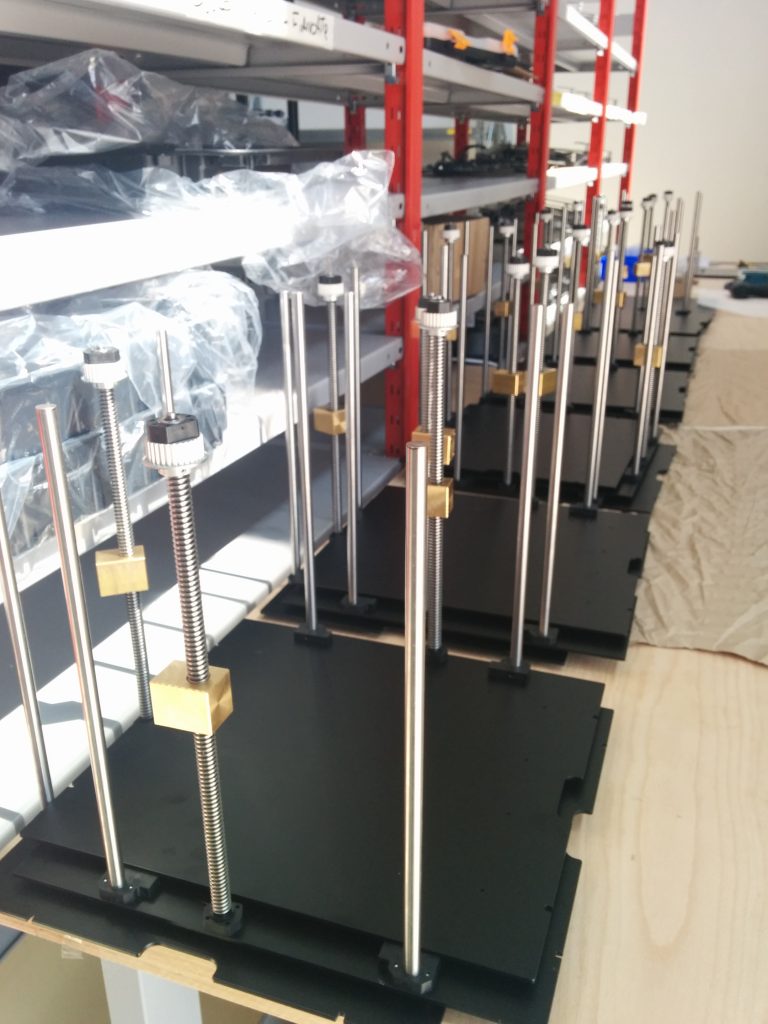

The day before the faire we had our share of hard work, as we had to physically move the 3 FABtotum we took with us from Italy, plus all the booth stuff and computers.

Fortunately we where mostly still running on a +6 timezone and we woke up at 6am so that everything was ready for entrance to the faire by 9:00 am.

Ignoring all the huge booths, we were probably the first ones to receave our exibitor badge! yay!

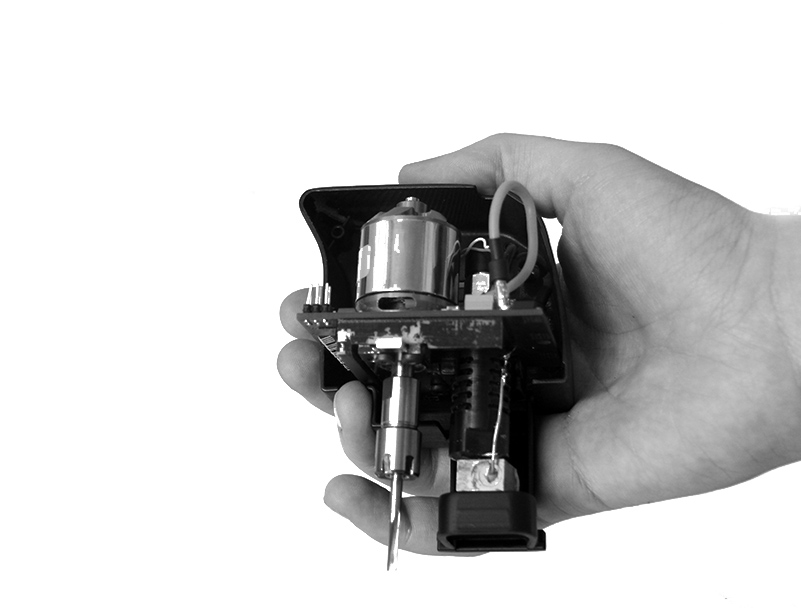

By the end of day one we where settled and started to run tests to recalibrate the machine after the travel. One unit, the white one, received too much love from the express courier and got damaged during shipping. we fixed it back to a usable state, and we used it to scan a coin during the weekend.

That evening they served Paella for free to all exibitors and workers, it was a nice way to close this busy day. I never seen so much Paella in my life, and it was delicous too.

Add free beer/drinks, nice guys all around , Electro Giraffe providing the soundtrack and the perfect party is served.

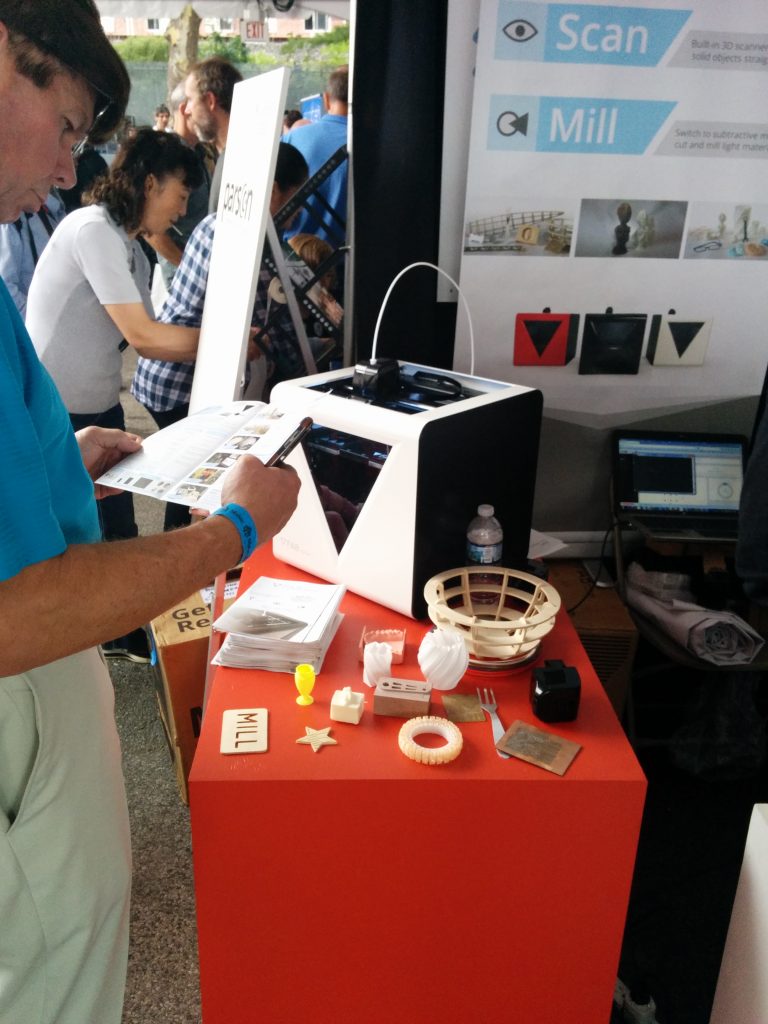

On Saturday, as soon as the faire kicked off, we where flooded with visitors.

We were visited by some Indiegogo backers too! Thanks for coming guys!

Backers where able to touch and interact with the FABtotum, hopefully showing all the work involved and the quality of the build!

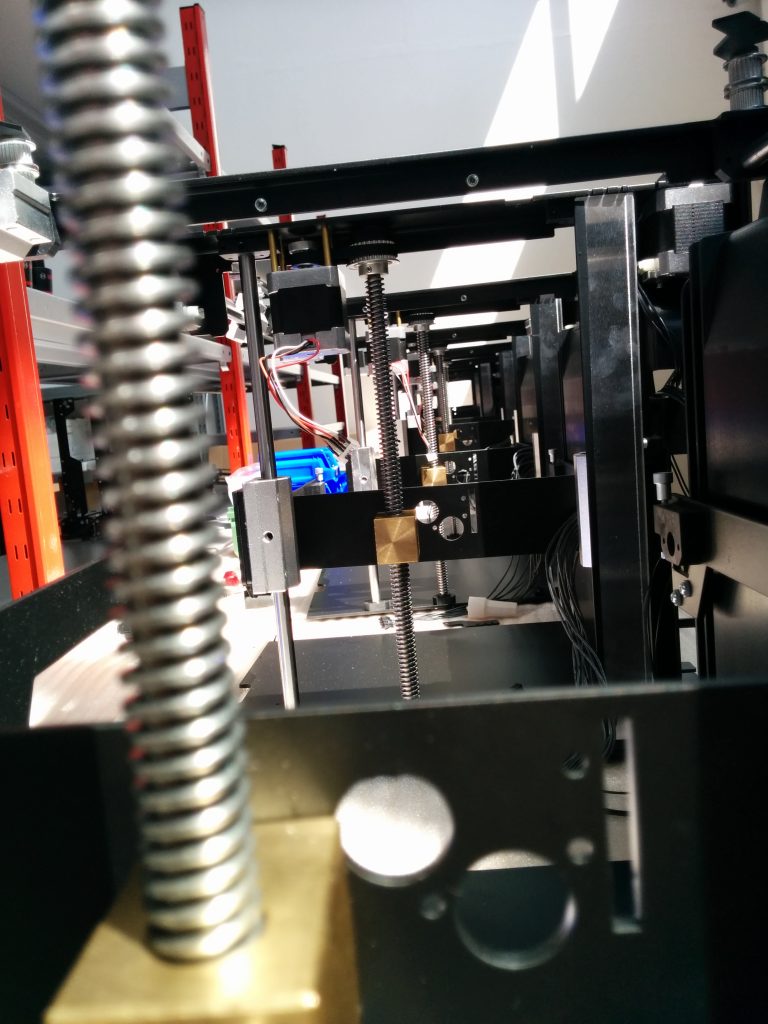

Many other exibitors came to see the FABtotum, and despite the small space we answered all the questions, from the simplest “how do you do that” to “how the belt system works”.

Notable visits were from Indiegogo’s Associate Director for tech & Hardware Ben Bateman, Arduino Co-Founder Massimo Banzi (who later made us blush with his tweet), and Maker Media Vice president Sherry Huss.

We where literally stuck for 2 days answering all the questions from the visitors of the faire, so we couldn’t see the faire ourself until the very last hour of Sunday, when we gave each boot 15 seconds time each before closure.

Finally, on Monday we had some rest before leaving.

We left Queens and visited Manhattan for the first time, wich was a little bit messy for the UN meeting but cool nonetheless.

In the evening we even had the chance to visit the NYC Resistor hackerspace.

the place is really rad! Andrea became really euphoric.

What an incredible city, full of contrasts and shades, diversity and communities!

No other place would be more suitable to host Earth’s “Greatest Show and Tell”.

On Tuesday we left the City. Our country needs us for the European Maker Faire Rome!

But this is just a goodbye, we’ll be back!