Colibri Effect Contest’s winners and other stories

Time’s up!

Fairs are all gone (for the moment), Easter Egg has expired, the Printing Head PRO awaiting time is matter of days, Colibri Effect Contest is over. It’s definitely time to sum everything up!

1. Fairs and Shows

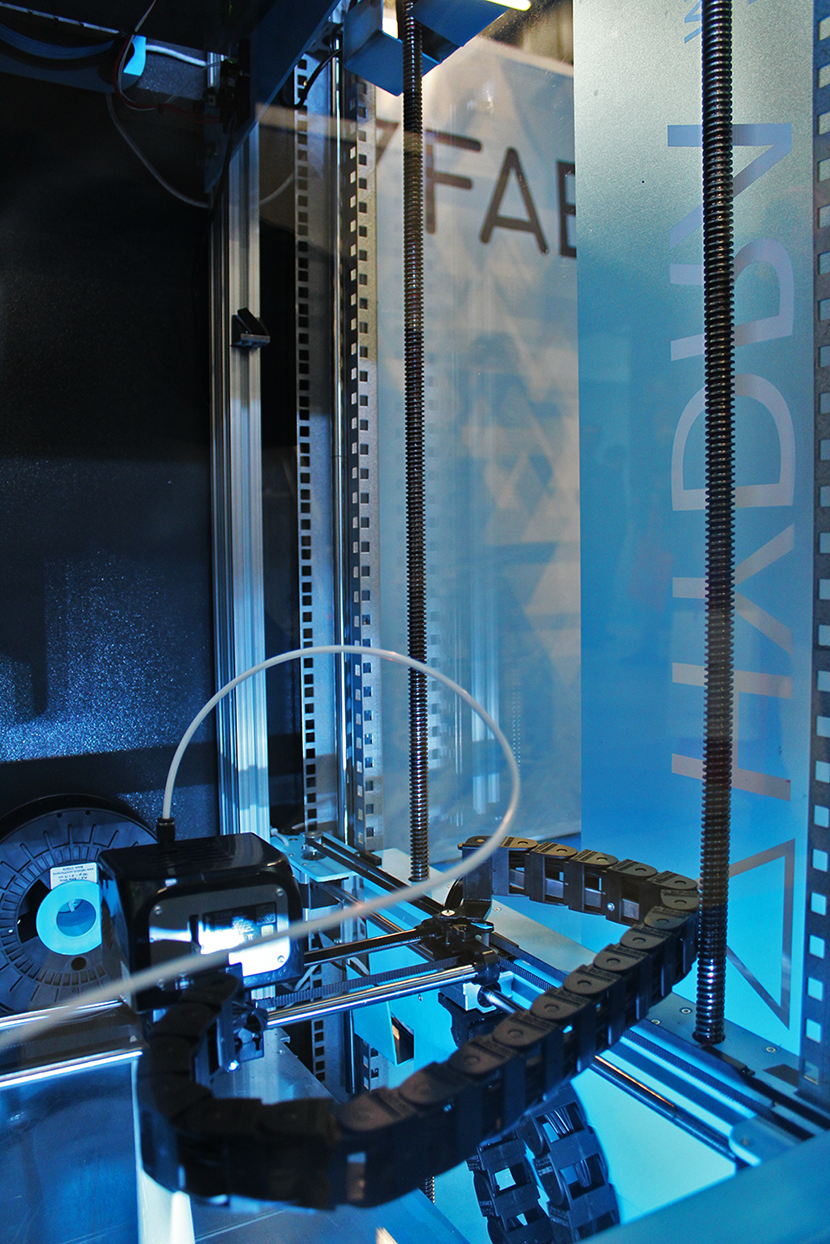

We have been roaming a bit around Italy and Europe: did you have the chance to meet us? We introduced our Printing Head PRO and Hydra. Have you read about them already? Have a first glimpse on our website!

People during the shows have always welcomed us and found our projects great. Some of you also joined us and discovered what we are working on, as well as the mentioned new products.

In the upcoming months we’ll try to be at other fairs: if we’re missing an important date let us know and if it is not 2017 maybe 2018 we’ll see us partecipating.

2. Printing Head PRO availability

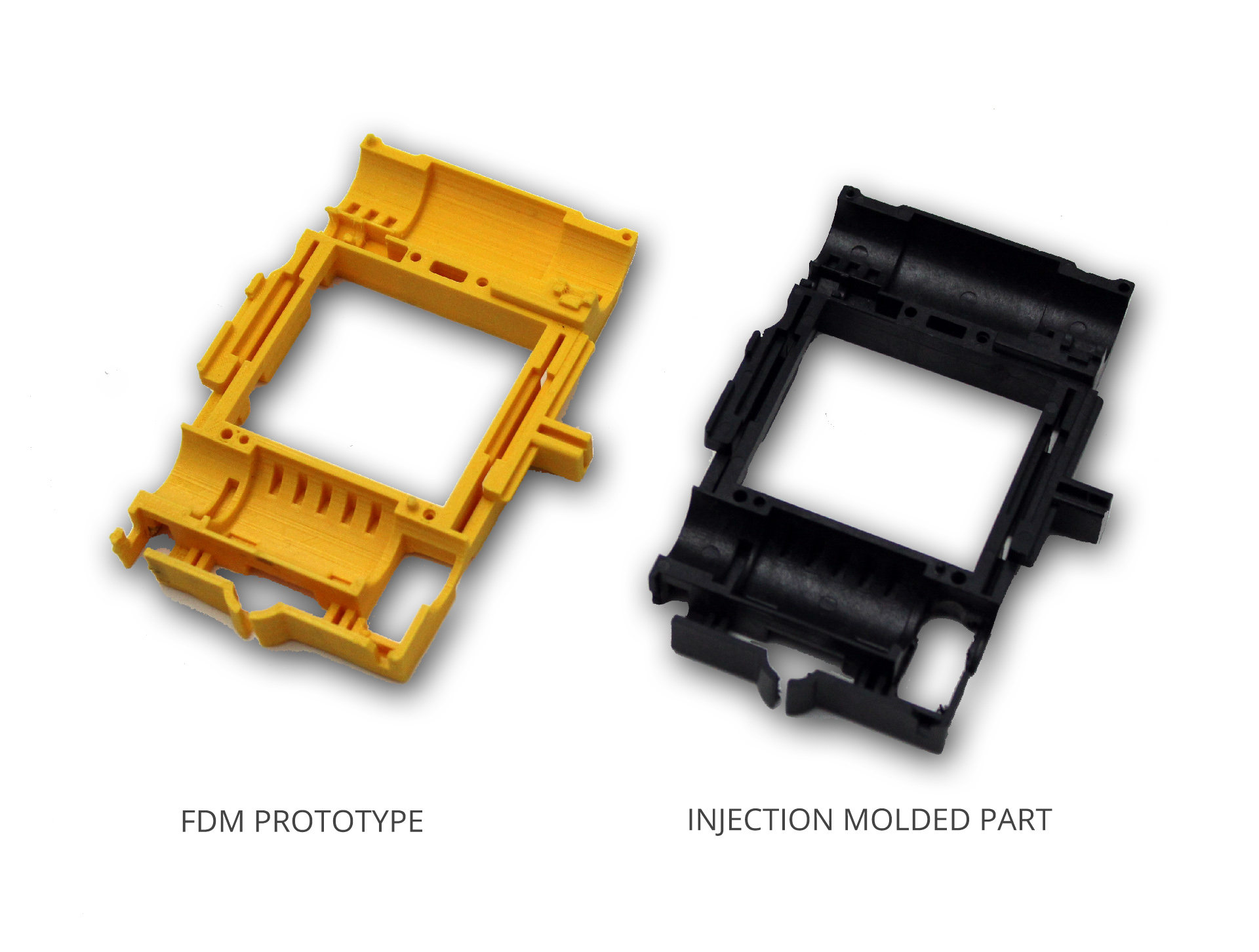

Introduced a while ago, now it’s at the final tests stage. In a few days it will be added on the store: a newsletter will follow soon after. We’re proud of the results, as quality of the prints is higher than ever and range of filaments is widening up constantly.

3. Colibri Effect Contest is over

After a beta testing period where many of our friends and users have been helping us troubleshooting, the very first FABtotum Colibri 1.0 version is ready to be used by everyone. Many features have been added, checked, tested.

This means the contest we lauched on the same time has come to an end, we have the five winners’ names! Congratulations to:

@christopherwit

@florentmaye

@homahe

@AndrewKillian

@dr4Ke

We really want to thank them as they really helped the Dev Team. A constant flow of reports, feedbacks and advices have overwhelmed them: that’s the purpose of having an Open Source project. This is a benefit both for you and us: we can have a better result, you have a better product. Easy.

The winners will be contacted via email within 8th of May in order to organize the withdrawal of the prize.

Again, thanks for being such a great community: a particular mention goes to the member of the Forums as well. Keep up the good work! It is a true inspiration for us to see that many “old fellows” are still with us and use their FABtotums for completely different projects. Their help to others, also, is a helping hand for Support Team.

Summing up, this period has seen us busy: all the Team members had a full agenda. We still have a lot to tell though. We’ll be back in May with our Community Highlights (if you want to be featured write us), we’ll get you precise dates for the release of the Printing Head PRO and more is just yet to come. Meanwhile, stay tuned.

Cheers and congrats to the Colibri Effect Contest winners!

FABteam