Sneak Preview: Hybrid Head V2, Laser Head and…

Hi everyone!

After a short break we are already back with some updates for you. Expect more in the near future, you’ll hear from us again really soon.

In the meantime we can tell you that, after two years from the start and one of production/deliveries, we have a bunch of new things that will be available in the upcoming days.

The Hybrid Head V2

We told you in the previous post that the Hybrid Head V2 is on its way: we’re not done yet with it though: we are still working on the last details; the final result will offer you the best performances ever and a better quality of prints.

While waiting for some smaller parts to be delivered and tested, we are already watching it printing fine objects.

In the picture below you can see some samples that show you the improvements: higher temperatures let us try different materials and we can proudly tell you we can print PLA, ABS and NYLON.

Samples of prints with the Hybrid Head V2

The specs are the ones previously released but we take the chance to sum them up:

- full metal body hotend;

- improved fans system;

- completely interchangeable nozzle (which means easier maintenance/replacing);

- completely interchangeable cartridge;

- different nozzle sizes available (we will tell you more later on);

- 260° max working temperature.

First pictures of the Hybrid Head V2: final look may still change

A new Feeder

The feeder mechanism has now become simpler and does not require any action to switch between additive and subtractive mode.

No more buttons to be pushed: new FABtotums will have a slightly different feeder and won’t have any hole on the back inner panel.

What if you already have a FABtotum and want this to be available on yours as well?

We will add a dedicated note on our wiki as you need to manually change it before switching to the new version from the settings of the FabUI.

This is something we decided to change as a consequence of the community’s experience. That’s why, once again, we are always looking for your feedback.

Scanning update

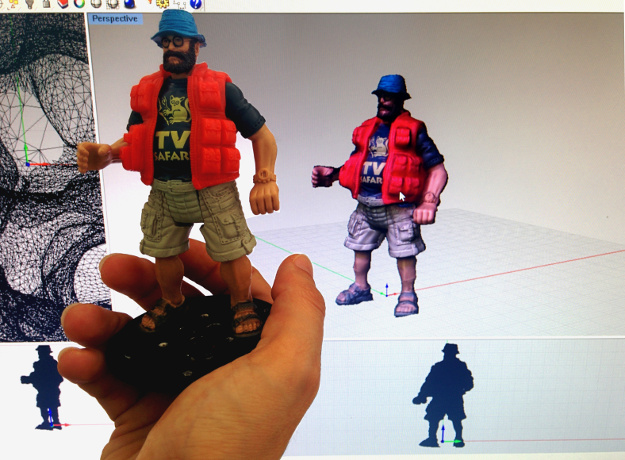

Out of the three first capabilities of the FABtotum, scanning option has always been difficult to be used. Results were not always reliable and satisfying. We worked hard on this as we wanted to offer you a better product. In the upcoming months we will focus even more to have you less stressed when postprocessing. Shapes will be less deformed, the camera is going to add colours and details to the final result. We will tell you more as soon as we have news and we will always update our development log on the forum as well.

Developing the scanner results

A more complete Wiki

First year of FABtotum’s life also gave us a better idea of which were the main obstacles between a bad print and a good one: 3d printing can require a bit of knowledge first and our machine as well need to be “discovered”.

To help you (and to help us as well) we are little by little completing the wiki: a lot of new contents have been added every now and then and still are. Our Team together with the community increased the literature available online so that troubleshooting and first steps became easier.

You can give it a look and find out yourself here

An idea of all the components of the FABtotum

All the documents are now on GitHub

We have gone even further than that: loyal to our Open Source identity, on Git Hub we added every missing specification. From hardware (already available on GrabCAD) to software, everyone can see what the FABtotum is made of and how it works. Suggestions are appreciated, simple curiosity is also welcome.

Here is where you can find everything

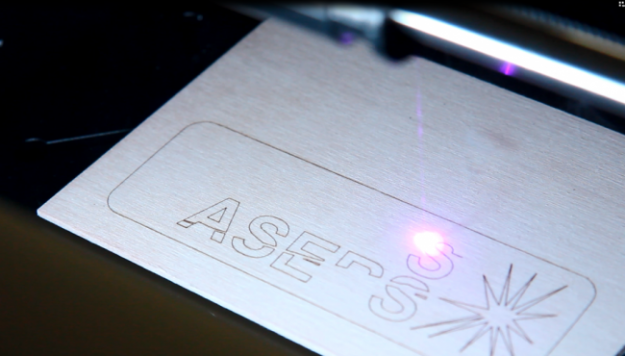

Laser Head

It has been in our projects since the beginning and it is now pretty much ready. We are still testing it, but the first results have seen our smiles rising and shining on our faces. It is not mentioned to cut hard and thick materials: we still prefer to leave this kind of job to the milling motor. Now you can throw away that smelly mutated seabass of yours.

With the laser head of the FABtotum you can:

- engrave woods, plastics etc;

- cut thin sheets of paper, cardboard and plastic.

You cannot:

- cut thick plastics or other thick materials (>0.2mm)

- pretend to be an evil scientist.

Testing the laser precision and quality

The new head won’t replicate the capability of the milling head. However, as you may know, laser engraving has a much more higher precision. You will be able to write or draw lines on the mentioned materials, as well as cut what would be too soft of thin for a drill bit.

The power of the laser we will use is 500 mW: nothing too powerful, just enough to do what’s needed.

This means that it won’t be too dangerous or require special equipments, but it will still be better to use a bit of extra care when turned on.

This is how it will look like, more or less:

First pictures of the Laser Head – final look may be slightly different

It will be easy to be mounted on the FABtotum and won’t require extra calibrations in addition to the ones you would normally do.

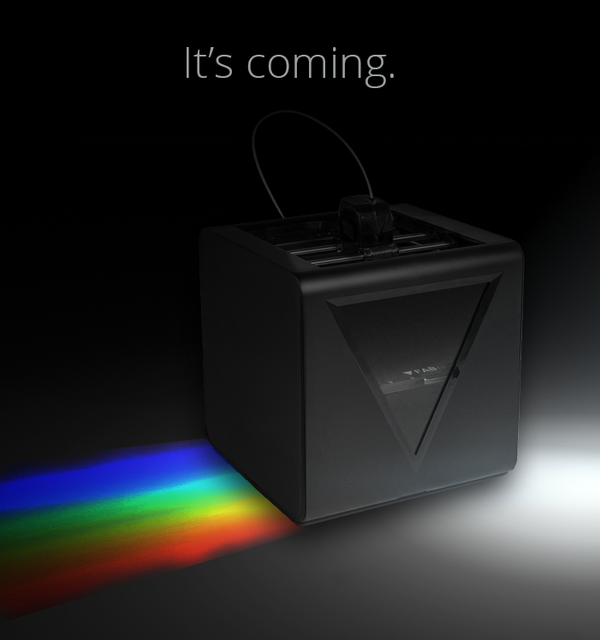

Coming soon…

Today, then, we can say we already pushed the envelope a bit further than the first idea of FABtotum, born two years ago on Indiegogo.

The three Heads: the V1, the V2 and the Laser Head

But, as said at the very beginning of this post, we still have other great news coming soon…

Keep following us!

*Available from next release, due on 20th August.