FABtotum’s Community Highlights: time to play!

Hi all,

we’re ready to share another story with you.

In these days many things are coming up, from events (have a look at our agenda!) to national holidays. But Giovanni Mancino, the protagonist of this Community Highlight, has so many projects alive he barely manage to get everything done right on time.

He has a small business starting up and here are a few ideas that came out of his FABtotum that will get him right where the people need him.

He has been using the FABtotum Personal Fabricator with an Hybrid Head and he got skilled little by little. Today he is pro user!

The Juventus Clock

Hard task for a guy who is an Inter FC supporter. You know italians are crazy for football. It was not too hard for the FABtotum though! This was one of his first tasks and was a gift for a friend.

Here is what it took:

- 12 hours of modeling;

- 14 hours of printing;

- 0.5 hours to get everything together and sand off where he got too far with tolerances (we all know how disturbing tolerances can be, right?)

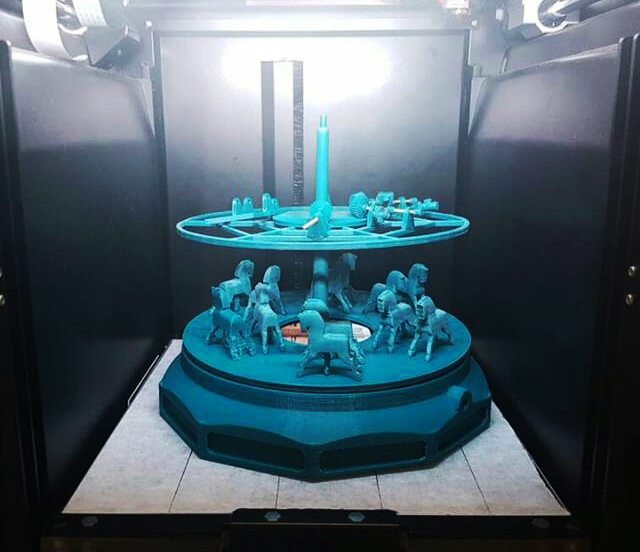

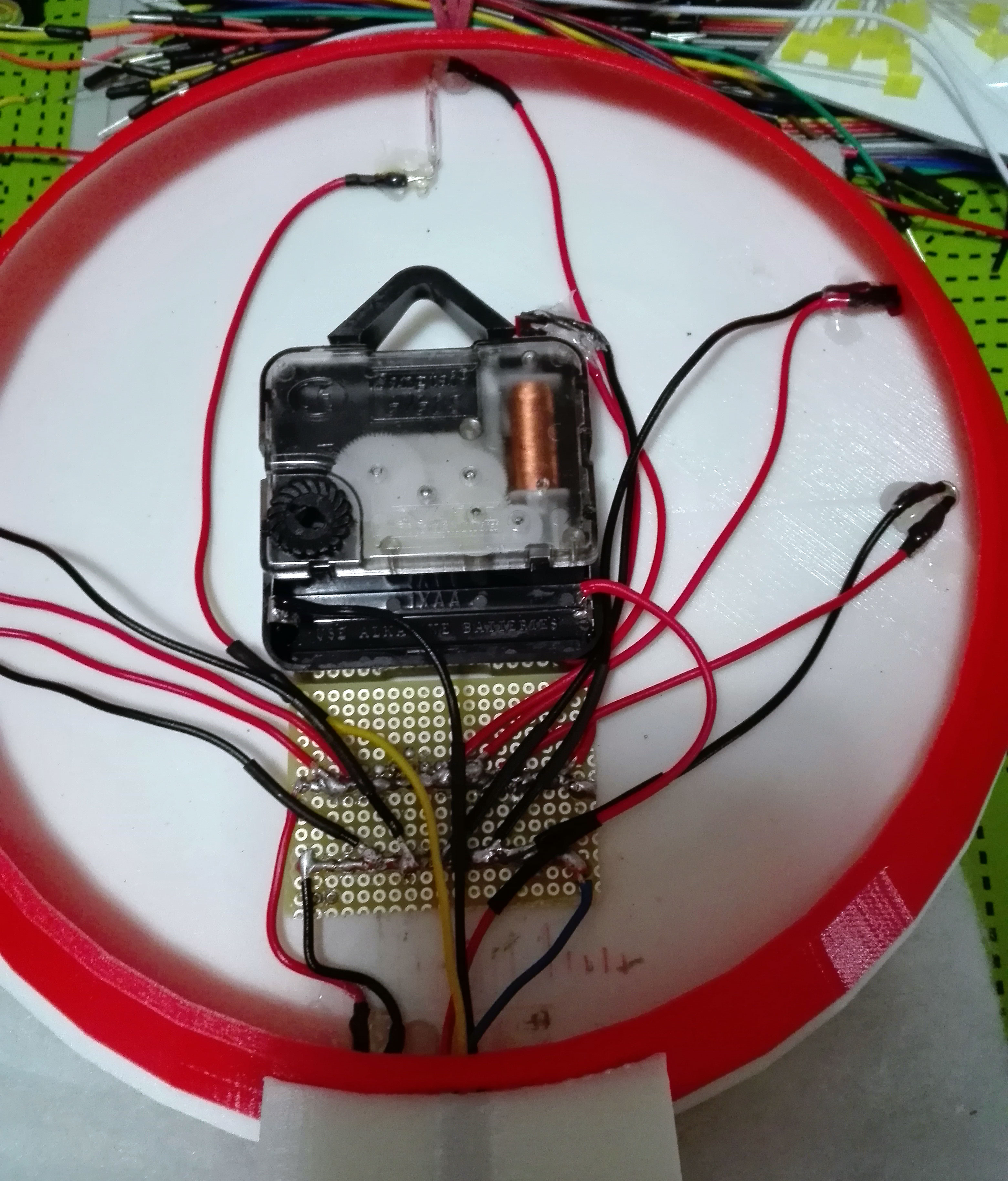

He used the colors of the team (black and white) and then designed a pink stand composed by two polygons forming the ball (the hexagon and the pentagon). The color represents the very first uniform, which had a pink t-shirt. As you can see from the pictures, he then needed to mount the motor and make the clock functioning. We’ll show you the picture of another clock he made just to get you an idea on how he could do this. So yes, he can 3D print clocks. Amazing right? But that’s not all!

And here you have the final look, of course it is completely functioning!

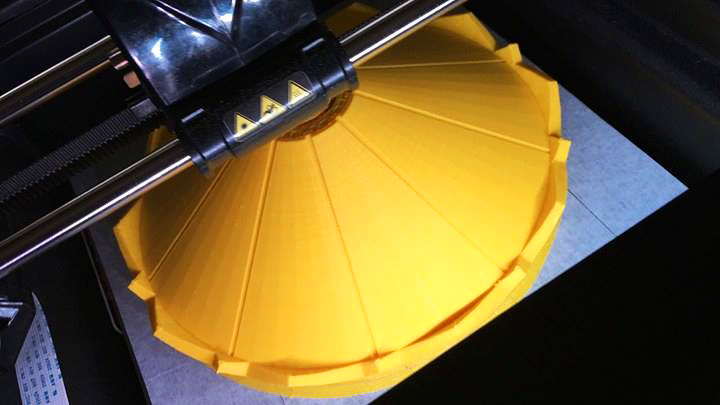

The Trumphets set

Here in Italy we normally give a small item as gift/souvenir for the special events. Everything is a good reason: from births to anniversaries, weddings, graduations, licences… just everything.

Giovanni made these cute trumphets for a guy who got his conservatory graduation in…well, that’s obvious, right?

Here is what it took:

- 1.30 hours of modeling;

- 3 hours of printing;

- 7.50 hours of post processing.

Reading the numbers it is easy to understand that the hardest part was the latest. Easy to shape, easy to print…with lots of supports. As you may know, supports are the materials printed to preserve quality when angles and curves can be too difficult. The extras will sustain the final object so that nothing gets damaged or of poor quality. Supports then need to be scratched off gently. Depending on the used slicing software, they can be different in thickness, shape, and distance from the object. They need to be carefully set, otherwise they can be useless or, in the worst scenario, they can even damage the print.

Giovanni used a scalpel to make sure that all the small 3D printed trumpeths were nice in their gold PLA structure.

We really love the final result (and we can barely think of him trying not to get crazy while removing all the supports, considering it took a whole night until 6am)! Detailed, shiny, cute: they’re perfect to celebrate a graduation!

So, congratulation to the trumphet player but to Giovanni as well! He will soon have a Facebook page, we’ll share the link as soon as available.

If you want to contact him, tell us, we’ll do the trick for you.

That’s all for today,

keep following us!