3D Printing filaments guide

Choosing the right filament

There are several materials that can be 3D printed, each one with different physical proprieties and working temperatures.

The FABtotum can load filament spools up to 210mmx55mm(OD,Thickness), with filament diameter in the range 1.75mm +/- 0.1mm

We strongly suggest using certified official FABtotum brand filaments, as they give more reliable results with our hardware.

You are however free to experiment and use different brands, as long as they use the same material class, diameter and temperature specifications.

See how to load or unload the spools in the load and unload a filament spool article.

Pre-flight check

If you are using a FABtotum filament you should not worry about the material too much, as extensive testing has been done to ensure good performances.

However you may also use third party filaments. In both cases always make sure to keep in mind the following:

- If you are using a Slicing Software profile be aware that it’s not meant as a fool-proof solution, and might be tweaked a little to fit each 3D printed object.

Sometimes a profile will work great regardless, but with the right tuning you might get better results in less time. - Always store the filament spool in a suitable place, far away from sources of heat, sunlight and humidity.

- Make sure that, if you are using a third party filament, the diameter of the filament is consistent within the tolerance of +/- 0.1mm. Make a few spaced measurement.

- Different filaments use different temperatures. When changing one spool to another which uses a different filament make sure to clean the nozzle at the previous material temperature first, then adjust the temperature, this helps cleaning the melting chamber (hot end) and nozzle.

- Always load and check if the filament is extruding manually (from the JOG menu).

- Make sure the spool is locked in place with the locking lever and it’s free to rotate. Have the Feeding tube pass below the back spool roller (under the spool itself) in order to avoid it becoming stuck in the spool once most of the filament has been extruded.

Suggested Temperatures

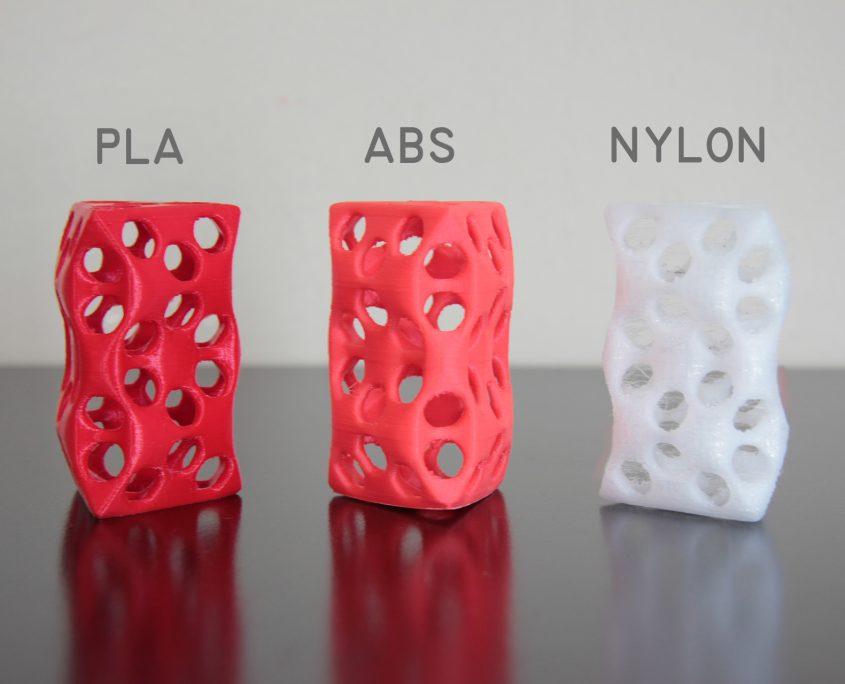

PLA (Polylactic Acid)

It’s one of the most used material in 3D printing: it’s a biodegradable polymer that comes from corn.

3D Printing suggested temperature: 200 – 220 °C

Bed temperature: 25 – 65 °C (bed can be at room temperature)

ABS (Acrylonitrile butadiene styrene)

It’s a common plastic polymer, it’s used to print strong parts. Having an higher glass transition temperature could be used to make parts that are used in hotter environments.

3D Printing suggested temperature: 220 – 260 °C

Bed temperature: 60 – 90 °C

NYLON

One of the stongest material you can find for 3D printing. It can be used for mechanical parts

3D Printing suggested temperature : 245°-255°C

Bed temperature: 90-100°C

Special Filaments:

Combining PLA or ABS with other additives can be possible and will result in different properties.

Charging the polymers with materials like Carbon fibers, wood dust, metallic powder can make stronger materials or with a nice finishing.

Printing settings depends on the polymer used. Refer to the spool manufacturer or , in case of FABtotum Filaments , the Spool label to get the suggested printing settings.

Flexible Filaments

Flexible filaments can be printed only with the Printing Head Pro

Due to the bowden extruder setup it’s -in fact – usually difficult to print flexible filaments like rubber or TPU with the Hybrid Head or the Printing Head V2.

Doing so will result in filament clogging the extruder and subsequent need to clean it.